The MGS Group

Wire, Cable, & Optical Fiber Handling and Twisting Equipment

SERVICE &

SUPPORT

Contact Our Sales Team Today.

We are here to answer all your pre and post sales questions.

MGS, Hall, and Northampton Machinery – Capital Equipment Sales

MGS, Hall, and Northampton Machinery – Spare Part Sales

Service/Engineering

-

Tom Beland - Service Manager - Americas

315-337-3350 ext.208 tbeland@themgsgroup.com -

Dave Lane - Service Manager - Rest of World

+44(0)1604-782220 ext.327 - USA 315-337-3350 ext.327, dlane@themgsgroup.com -

Tom McComiskey - Vice President

315-337-3350 ext.203, tmccomiskey@themgsgroup.com -

Bob Sandore - Electrical Engineering & Field Service Manager

315-337-3350 ext.134, rsandore@themgsgroup.com -

Randy Witzigman - Mechanical Engineering Project Manager

315-337-3350 ext.147, rwitzigman@themgsgroup.com

About The MGS Group

The MGS Group is the home and management arm for industry giants: MGS Manufacturing, Hall Industries and Northampton Machinery. Under The MGS Group guidance, we have combined complimentary machinery businesses focusing on the wire, cable, fiber optic, hose, tube, and related industries. Attention to detail has insured our product design reflects quality, durability and fit for purpose in the engineered machinery marketplace.

Our Locations

- MGS Manufacturing, Inc.

-

122 Otis St.

PO Box 4259

Rome, NY 13441 - Tel 315.337.3350

- Fax: 315.337.4502

- Hall Industries

-

8C Commerce Dr.

North Branford, CT 06471 - Tel 203.481.4275

- Northampton Machinery Co. Inc

-

7 Deer Park Road

Moulton Park Industrial Estate

Northhampton NN3 6RX England - Tel +44(0) 1604 782220

Our Product Categories

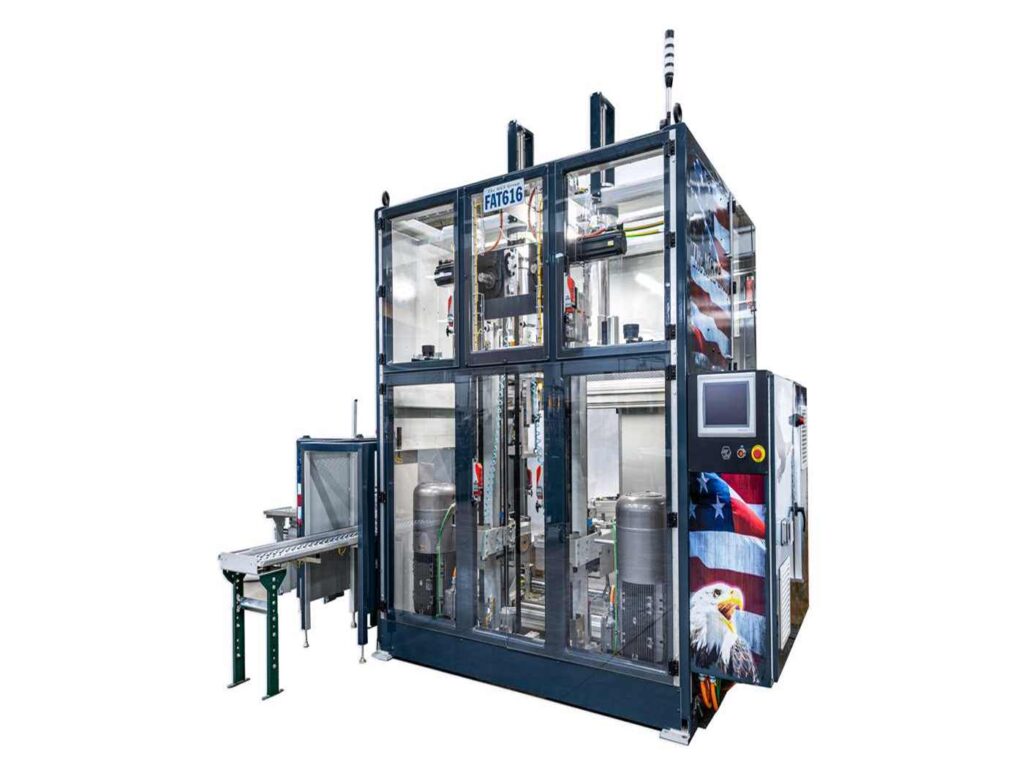

Rotational Equipment

Fully Automatic Take-Ups

Wiring Cable Handling

Upcoming Trade Shows

Keep up on our events

WIRE EXPO 2026, Milwaukee, WI

IWCS 2025 – Pittsburg, Pennsylvania

WIRE 2026 – Dusseldorf, Germany

Engineering Driven

We are in the business of solving problems.

Design

Machinery and Control Systems optimized to your application. Our comprehensive design and engineering capabilities and personalized service will supply you with ruggedly built equipment for decades of reliable, consistent, and profitable service.

Automation

Our skilled and experienced engineers design, produce, and implement all levels of automation. From a single automatic spooling machine to fully automatic online packaging systems, The MGS Group can automate your process insuring the highest levels of efficiency and productivity.

Integration

We don’t stop at producing a piece of equipment, we integrate it into your manufacturing environment. Our engineers will design to interface your MRC systems, collect data for SPC, or simply work seamlessly with existing manufacturing lines.

Customized Solutions

Involve The MGS Group early on in your product manufacturing process. We will work tirelessly to design a comprehensive, automatic, efficient, manufacturing process to insure your success. We routinely design our machines to make the most of the latest automation technology putting your manufacturing solutions ahead of the competition.